What makes up a SCADA control system?

Supervisory Control and Data Acquisition (SCADA) systems are becoming increasingly essential across a variety of industries as a way for asset owners to maintain efficiency, process data for informed decision making, reduce costs, communicate issues to prevent downtime, and comply with relevant health and safety, and engineering standards. In this introductory article, we look at the different elements that make up a SCADA system.

SCADA is a computer-based control system used to gather and analyse real-time data from remote devices to monitor and control equipment. SCADA systems are used in a wide range of industries, including water and wastewater, power and energy, mining, food and beverage, transportation, defence, and infrastructure, among others.

The basic architecture involves programmable logic controllers (PLCs) or remote terminal units (RTUs) which communicate with, and collect data on, different types of process equipment including machinery, pumps, flow/position/level sensors and many other devices. This data is transmitted to centralised computers with SCADA software where it is processed, distributed, and displayed so that operators can analyse it to make informed decisions.

SCADA systems can be found in a large range of applications including, achieving quality standards at wastewater treatment plants, energy management for critical infrastructure, and ensuring production and safety at manufacturing facilities, to name a few.

SCADA systems are also subject to a number of national and international standards covering how the equipment is used and installed, along with functional safety. This is vital to ensure the systems are safe and reliable.

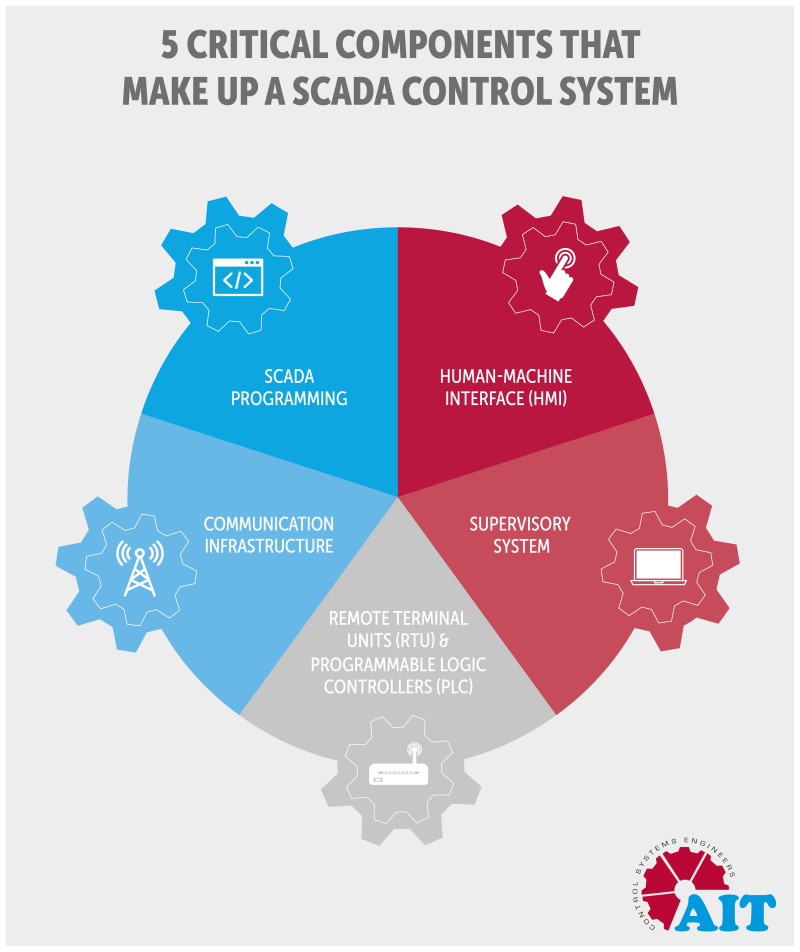

Looking at the overall makeup of a SCADA system, there are five critical components:

1. Human-Machine Interface (HMI)

A Human Machine Interface, or HMI, is an input-output device that has a display screen which is linked to the SCADA program and databases. It provides management information for operators such as scheduled maintenance procedures, operator controls, schematics, logistic information, and trending and diagnostic data for specific sensors and machines.

This information can then be analysed and used to make informed decisions.

2. Supervisory system

The supervisory system is used to relay data from equipment such as RTUs, PLCs and sensors to the HMI or other display interfaces which are typically located in a centralised control centre or and at various site locations.

Smaller supervisory systems may contain a single computer or HMI while larger systems may contain distributed software applications, disaster recovery sites and multiple servers that are configured in a redundant formation, such as hot-standby. The supervisory system continuously monitors and controls operations to maintain the safety and integrity of the SCADA system.

3. Remote Terminal Units and Programmable Logic Controllers

Remote Terminal Units (RTU) are electronic devices controlled by a microprocessor that are used to interface to field equipment with the SCADA system by transmitting telemetry data to the supervisory system. RTUs are also used to receive messages from the master control system which monitors and controls connected field equipment.

Programmable Logic Controllers (PLCs) are computer control systems that are connected to equipment and sensors via input and output signals which are converted into data. PLC systems are usually ‘closed’ or separate from other IT systems such as LAN, WAN or corporate networks, this ensures the integrity and safety of the control system.

4. Communication Infrastructure

Communication infrastructure for SCADA systems can vary between applications depending on the size and requirements of the system.

Factors that need to be considered when designing or setting up a communication network include existing communications infrastructure, budget, data protocols, speed of transmission, line of sight for radio networks, criticality (including redundancy requirements) and ability to accommodate future needs.

Communication infrastructure is essential to SCADA systems, especially in applications where assets are distributed over a large geographical area.

5. SCADA Programming

In order for a SCADA system to function correctly and safely, it requires thorough knowledge of not only the engineering process being monitored and/or controlled, but also the programming language and associated standards.

There are various formats used in SCADA programming, and most modern SCADA packages have their own in-built libraries consisting of icons and other visual display tools.

SCADA programming requires knowledge and experience to master as there are a lot of factors to consider. If done correctly the system will perform flawlessly for many years, however if installed incorrectly the system would likely become unstable, causing extensive damage including potential loss of life.

An automated advantage

According to Geoff Bladon, Business Development Director at Automation IT, it is important to choose a SCADA systems integration company that provides a complete SCADA solution that is of high quality, meets the engineering standards, and complies with health and safety legislation.

“These five components play a critical part in the operation of a SCADA system. While project costs do need to be taken into account, clients should focus on the total cost of ownership for these systems,” Mr Bladon said.

“The cheapest option might not be the best if the equipment doesn’t meet standards, or if the programming is done poorly and without proper documentation. These can make a difference on the efficiency and productivity of a site, as well as the ease of future upgrades. Some lower cost options actually take a lot more engineering time to deliver the same result as what appears to be a more expensive option.

“At Automation IT, our certified, degree-qualified engineers focus on providing clients with a high value end-to-end solution that meets their individual requirements, as well as ensuring the system complies with all laws, standards and warranties.”