CONDITION MONITORING

Condition monitoring is the process of monitoring equipment parameters such that a significant change is indicative of a developing failure. It is a major component of predictive maintenance. The use of conditional monitoring allows maintenance to be scheduled, or other actions taken to avoid the consequences of failure, before the failure occurs.

Measurements are required of physical quantities: temperature, pressure, flow, speed, displacement, according to the plant item. Absolute accuracy is rarely necessary, but repeatable data is needed.

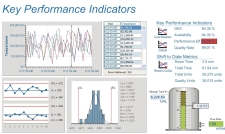

Service predictions are made by performance analysis, where the physical efficiency, performance or condition is found by comparing actual parameters against an ideal model. Such parameters provide an overall health index where deterioration is typically the cause of difference in the readings.

In some cases, it is possible to calculate the optimum time for equipment overhaul to restore degraded performance.

Condition monitoring is a proven solution that could save your site millions of dollars per year.

PROCESS IMPROVEMENT

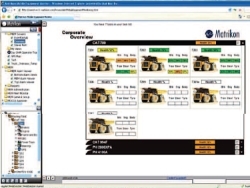

Automation IT is able to install software systems which are able to identify, analyse and improve various processes within your organisation. This process enables our clients to increase efficiency, reduce downtime and ultimately increase profitability of their assets.

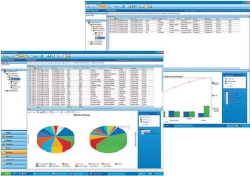

This outcome can be achieved in multiple ways including identifying bottlenecks, analysing production downtime causes, calculating key performance indicators and reporting the relevant information in a clear and concise format to the appropriate people allowing them to make the correct decisions at the right time.

Automation IT is able to improve standard processes of companies in all industries including:

- Manufacturing

- Power

- Mining

- Food & Beverage

- Water and Waste Water

MANUFACTURING EXECUTION SYSTEMS (MES) & INDUSTRIAL IT

|

Is your plant producing 100% output all of the time? Can you reduce costs while improving quality? Can you increase production on a line? What is MES software? How can it help your plant?

|

PROCESS IMPROVEMENT

Automation IT is able to install software systems which are able to identify, analyse and improve various processes within your organisation. This process enables our clients to increase efficiency, reduce downtime and ultimately increase profitability of their assets.

This outcome can be achieved in multiple ways including identifying bottlenecks, analysing production downtime causes, calculating key performance indicators and reporting the relevant information in a clear and concise format to the appropriate people allowing them to make the correct decisions at the right time.

CONDITION MONITORING

Condition monitoring is the process of monitoring equipment parameters such that a significant change is indicative of a developing failure. It is a major component of predictive maintenance. The use of conditional monitoring allows maintenance to be scheduled, or other actions taken to avoid the consequences of failure, before the failure occurs.

SOFTWARE AND DOCUMENT CHANGE MANAGEMENT

By implementing a change management system it is possible to create a single portal where everyone is able to view all of the information from one secure location. In addition to consolidating data it is also possible to control all modifications made to the information, maintain a full audit trail of historical changes, compare versions of files, create backups of all historical changes and set different user privileges, allowing users to only view and change the files that are relevant to them.

TRAINING SERVICES

Training is often an area that is overlooked by engineering firms and as a result the needs of end users to understand their newly implemented control system are neglected. Automation IT recognises this fact and has tailored a series of training courses to ensure that Automation IT customers always have access to specialised training should it be required.

An experienced instructor is provided to guide the student using demonstrations and hands on lab exercises so they are prepared to develop control solutions.

Modules can be scheduled as required but students should have a working knowledge of PLC's, industrial electronics and be computer literate before completing a Module.

Training courses are available for most major brands of PLC and SCADA software and hardware and can be categorised as follows:

|

Our courses can also be tailor made to suit the level of personnel and the type of equipment used. Contact us for more information.

ENGINEERING SERVICES

Automation IT's experience in control system design and implementation is undisputed. Since its establishment in July 2000, Automation IT has completed literally hundreds of control system projects ranging in size from small single PLC and SCADA applications up to large turnkey projects encompassing high voltage control, process control, electrical design, installation, drafting, site simulation and detailed site acceptance testing. This experience and professionalism, along with a high level of repeat business, ensures that customers can be confident they have the right company for the job.

Click on the industry links below for more information or click here to request contact from a member of our sales team.

Automation IT’s Health & Safety, Environmental, Quality (HSEQ) & Risk management system is Third Party certified to ISO 45001 / ISO 14001 / ISO 9001 / ISO 31000.

Electrical EngineersAutomation IT is able to provide a complete spectrum of Automation services from maintenance and support contracts to complete turnkey solutions.

24 x 7 Support ServicesAutomation IT provides a dedicated 24x7 support service via our Brisbane head office.

|

MES & Industrial ITOur IT division specialises in providing customised solutions for a range of problems faced by both operations staff and management of large organisations.

|

|

CAREERS

Current vacancies

With ongoing success in the field of control systems engineering Automation IT are proud to present opportunities to engineers looking to be treated as more than just a number or a commodity. In the modern engineering world our focus is on nurturing flexibility to our staff and customers alike, this means maintaining proven engineering methods whilst thinking outside of the square to deliver projects in a manner that is never boring and listening to ideas to continually improve our processes.

Where do your passions lie within the field of Control Systems? We have opportunities in Brisbane and Perth across Project Management, Design, PLC, SCADA, Commissioning, Functional Safety and Service Work to mention but a few.

The ideal candidate will have a strong focus on team work, be forward thinking, have an aptitude for solving problems, have a tertiary degree in engineering, have experience with the control system life cycle from design through to commissioning, have experience with Functional Safety, and have a willingness to continue to learn and be challenged.

Automation IT is an established Australian owned Control Systems Integration Company offering employees the opportunity to work at the forefront of many vertical markets alongside a team of engineers who enjoy working for one another.

Interested parties should submit a covering letter and resume to This email address is being protected from spambots. You need JavaScript enabled to view it.